First project at our new location

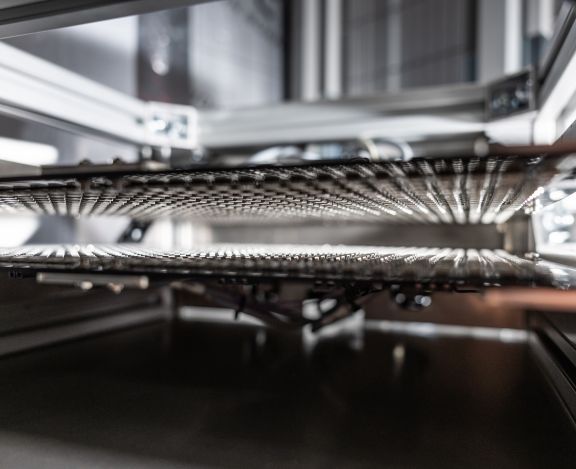

This development and validation tool is also the largest project in the history of ZEST-Innovate. This advanced system will be used to validate products under extremely stable and constant temperatures. This allows the ultimate thermal influences of the product to be investigated and tested.

Thermal validation and stability

In thermal validation, stability is essential. The machine maintains exceptionally stable temperatures, so that even the smallest changes can be measured. This is important to ensure that products remain reliable under different conditions.

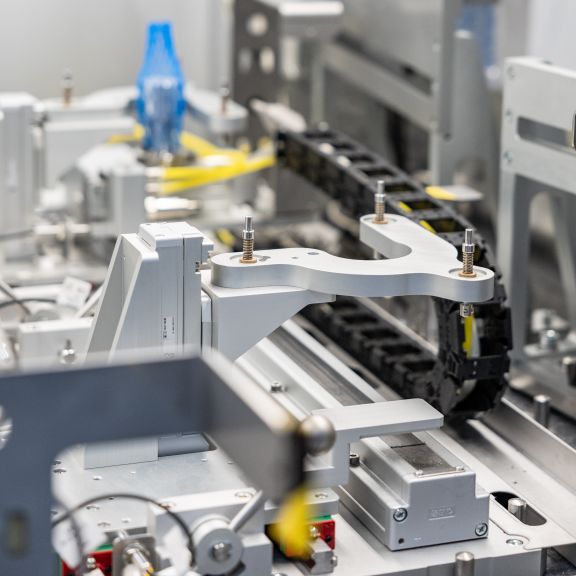

Automated test cycle with robot support

The system works with a repetitive cycle and is fully automated, with a robot supporting the process, says Willem van Reisen.

High tech module testing and optimization

The machine also monitors and tests the high tech module, and intervenes in case of deviations to facilitate troubleshooting and data analysis. This validation helps to optimize both the high tech module and the overall production process.

Developed entirely in-house

This complete machine, from design to implementation, is developed by us. The showpiece is the combination of stable flow and temperature control, which is essential for reliable thermal testing.

Ready for assembly at the customer's premises

After successful testing, the machine is now dismantled and cleaned, to be reassembled at the customer’s site. Before the machine is installed at the customer’s site, it is fully assembled and tested in our workshop. Every component has been carefully checked and tested to ensure that everything functions properly. The machine is then dismantled and the different modules are taken separately to the cleaner for thorough cleaning and packaging.

The final phase

In the final phase, the machine is reassembled by our own ZEST team in the customer's cleanroom. Our engineers ensure that the system is fully operational and fine-tuned, ready for use.

Do you also want to validate your products under extremely stable conditions and measure thermal influences down to the smallest detail? Contact us and discover how an advanced validation tool can optimize your processes!