OUR PROJECTS

Below is a selection of some of our projects. You can always contact us for our full range of services. Make an appointment and we will be happy to welcome you at ZEST-Innovate.

Secure Syringe Filler

- 23-10-2025

Together with the customer, we developed an automated filling system that minimizes fluid loss and operates with micrometer-level precision, from initial concept to tested end product.

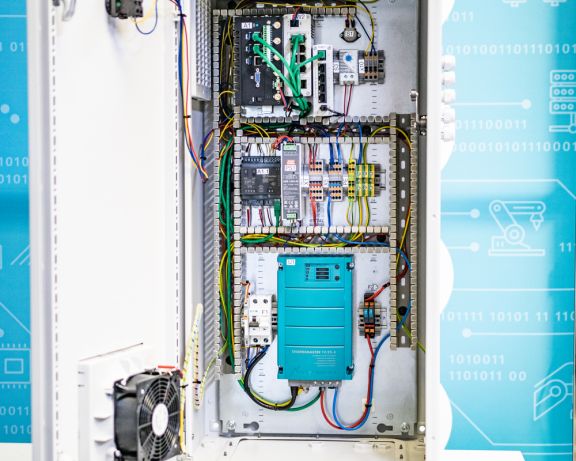

Read moreAssembly cells ensure complete process monitoring and a streamlined production process

- 30-09-2025

At Zest-Innovate, we have developed and delivered seven different production cells. These cells enable efficient product assembly while continuously monitoring every process step.

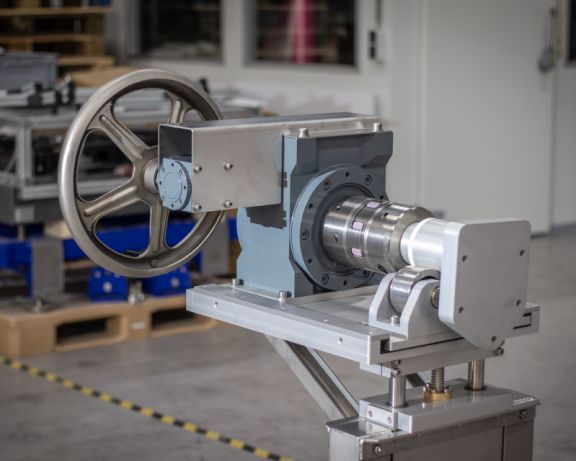

Read moreRotation tool for High-Tech assembly

- 24-03-2025

The team developed this solution. A rotation tool with detachable interfaces, specially designed for effortless and safe manipulation.

Read moreBuild-To-Print assembly (BTP): transport and storage tool for a high-tech semiconductor module

- 17-03-2025

A recent project concerns a transport and storage tool for a high-tech semicon module. This tool ensures accurate positioning and protected handling of critical components within the production process.

Read moreCustom designed mounting stands to optimize pre-assembly of sub-modules

- 14-03-2025

The modular design makes the trestles suitable for various variants and dimensions. A smart solution that contributes to a streamlined and efficient production process!

Read moreHigh Tech module for the Semiconductor industry

- 09-01-2025

This development and validation tool is also the largest project in the history of ZEST-Innovate. This advanced system will be used to validate products under extremely stable and constant temperatures.

Read moreParticle Testing Toolbox

- 05-09-2024

Advanced particle meter for optimum quality control. This solution, known as the Particle Testing Toolbox, enables companies to detect even the smallest particles, with a measurement range of 0.1 to 1.0 μm.

Read moreReview: new series-worthy generation of camera masts

- 22-08-2024

This new generation of masts can be read and operated remotely, with full compliance with all electrical guidelines, including EMC effects.

Read moreDesign Verification Tool for the Semiconductor Industry

- 15-04-2024

A new design verification tool for customer machine developments.

Read more